Examples

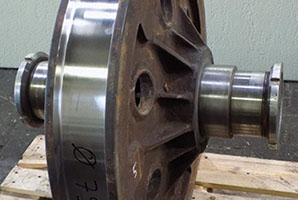

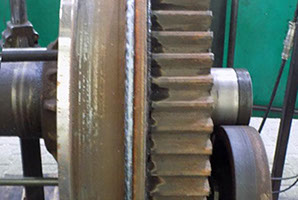

Even after longer service times, crane

wheels and rail wheels can be repaired

to a like new condition in 90 to 95% of all

cases.

As a certified welding company, we offer

the complete overhaul of crane wheels

and rail wheels of various types,

considering the relevant standards and

regulations.

Wheel diameter: up to 1,250 mm

Types: with / without tyre

Costs: approx. 30 – 60 % of investment new parts,

depending on the degree of wear

Period: 10 working days, can also be planned for short downtimes

Maintenance of crane wheels and rail wheels /

Repair welding

Non-destructive test methods (NDT)

Build-up welding /

Repair welding

• Visual testing (VT) Level 2

• Magnetic particle testing (MT) Level 2

• Penetrant testing (PT) Level 2

QM system according to ISO 9001 : 2015

Certified Welding Company

– DIN EN 1090-1, -2, -3 EXC 3 / steel and aluminium structures

– DIN EN ISO 3834-2, -3 / mechanical engineering

– WPK according to EN 1090-2 EXC 3 with -marking,

declaration of conformity

– Welding engineer (International Institute of Welding)

Scope of services:

• Information assessment

• Rough turning of wheel surfaces

• Surface welding of wheel surfaces

to restore the geometry

• Determining and documenting the

absence of cracks using NDT

• Turning to size

• Complete assembly

ISRR Industrie Service Rhein-Ruhr GmbH

Hülsermannshof 9A · D-47179 Duisburg

Phone: +49 203-4 85 51-0 · Fax: +49 203-4 85 51-51 · info(at)isrr-gmbh.de